The cheap, abundant substance that could revolutionise how we store energy

Solar and wind power are vital to meeting our current and future energy needs but they don’t generate electricity 24/7. So to ensure our power system stays reliable as more renewables come online, we need energy storage.

And a good deal of that storage currently comes in the form of lithium-ion batteries – the same things that power your phone and laptop.

They also include the large batteries unveiled by Tesla on the nightly news as well as the batteries in your electric car and the ones hooked up to your rooftop solar system. Lithium-ion batteries are everywhere.

The problem with lithium is that it’s an extremely limited resource, making up less than 0.002% of the Earth’s crust. Lithium’s scarcity makes it expensive, and the price will probably go even higher as the global demand for storage keeps rising.

Enter sodium. One of the two elements in ordinary salt, sodium is as cheap as (salted) chips and has a near-unlimited supply. And thanks to a team of world-leading researchers from the University of Wollongong (UOW), inexpensive and reliable sodium-ion batteries are only a few years away.

How it works

Supported by $2.7 million of ARENA funding, the $10.6 million battery project will develop modular, expandable sodium-ion batteries optimised for renewable energy applications.

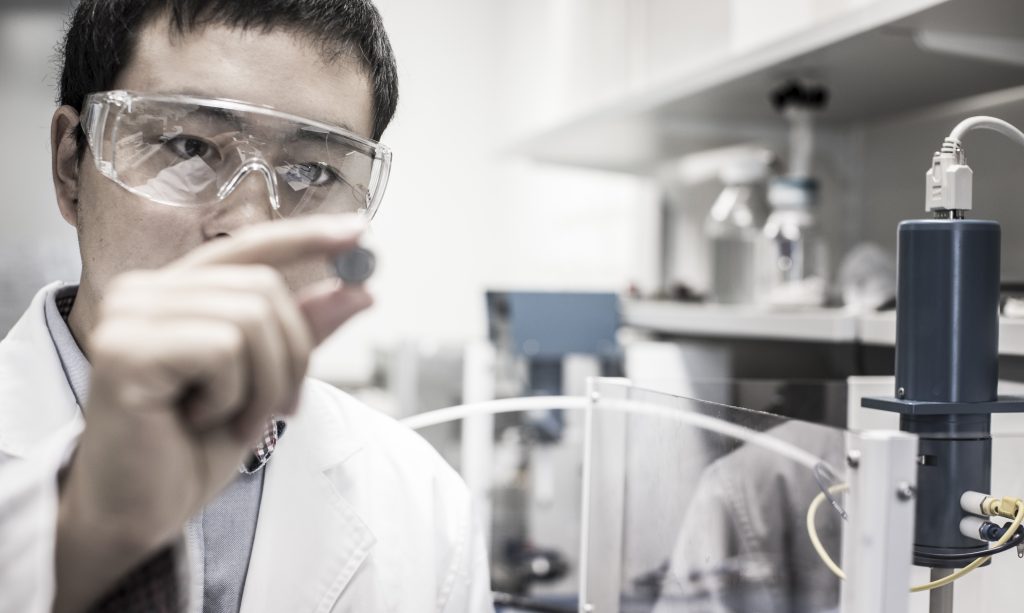

The researchers are currently working out the sodium-ion chemistry that is best suited to large-scale applications. They have partnered with leading Chinese manufacturers to develop the sodium-ion cells and make them into 5 kilowatt-hour (kWh) packs that can be stacked together to create any size battery.

“Sodium-ion batteries are a field receiving intense research interest,” says Professor Shi Xue Dou, who leads the project.

“However, much of the work has been on the lab-scale development of materials. This is one of the first projects to focus on scaling up the production of sodium-ion materials and establishing the production capacity to manufacture sodium-ion battery cells at a commercial scale.”

“We’ve had to develop a number of innovative approaches to address the issues that arise in scaling up this cutting-edge storage technology.”

Real-world testing

The battery packs will get their first proper test at the Illawarra Flame House, an award-winning sustainable home on UOW’s Innovation Campus.

“We’ll be testing a single module in a residential-type application,” says Project Manager Jon Knott.

“The Flame House can be hired out, so it’s often full of people. That means we can get usage patterns and start to see how the battery charges and discharges, and what sort of degradation we can expect to see in real-world batteries.”

Solar, sodium and sewage

The big test will come in 2019, when project partner Sydney Water installs a 30 kWh sodium-ion battery at their sewage pumping station in Bondi. The battery will be charged by solar panels on the pumping station roof and controlled by a UOW-developed energy management system (EMS).

“The EMS is a set of software controls and algorithms that figure out the best way to use power,” Knott says. “If the solar panels are generating, should you use that power straight away, use it to charge the battery or sell it back to the grid?”

Pumping stations have fairly unpredictable energy requirements – the pumps turn on and off automatically depending on the level in the tanks. That means the EMS needs to be extremely intelligent to plan for the station’s upcoming power needs. It could even check the weather schedule.

“If the system can predict there’s going to be five sunny days in a row, we can perhaps empty the batteries a little bit more than we could if we knew it was going to be raining,” Knott says.

“Installing cheap sodium-ion storage is about more than just reducing Sydney Water’s electricity bill,” says Dr Heri Bustamante, Principal Scientist, Treatment at Sydney Water.

“It also increases resilience by integrating renewable energy technologies into our infrastructure and processes. If a pumping station loses power, it can’t pump, which leads to messy and environmentally disastrous sewage spills. Reliable energy storage can ensure the sewage network keeps operating, even during extreme weather or natural disasters.”

“Part of the reason why we’re in this is to see if we can run pumping stations off grid,” says Ruben Muller, Sydney Water’s Resource Management Advisor. “For example, we’ve got a pumping station in the Blue Mountains where there is a risk of losing grid supply during bushfires. We could run a second feeder to it from another direction, or we could just install solar and a battery, which I think is a much better solution.”

Does size matter?

So if sodium batteries can deliver comparable performance at a lower cost, do we even need lithium any more? According to Knott, both technologies most likely have a place in the future of energy storage.

“Sodium is a larger atom to start with, so sodium-ion batteries are always going to be larger than a lithium battery,” he says.

“Lithium is good for phones and electric vehicles where you want light, small batteries that have a lot of energy. But in a house or industrial application where you’ve got batteries hanging on the wall or sitting on the floor, it doesn’t matter if they are a little bit bigger or heavier. Sodium can be a sister technology.”

This article was originally written by Simon Mitchell, Journalist.

LIKE THIS STORY? SIGN UP TO OUR NEWSLETTER

ARENA