How Aussie solar could power a new space race

Picture a world where satellites and self-navigating planes beam high-speed wireless internet to people from Adelaide to the Arctic, all of it powered by Australian solar technology.

That vision might not be too far from reality thanks to a group of solar-cell specialists from the University of NSW (UNSW).

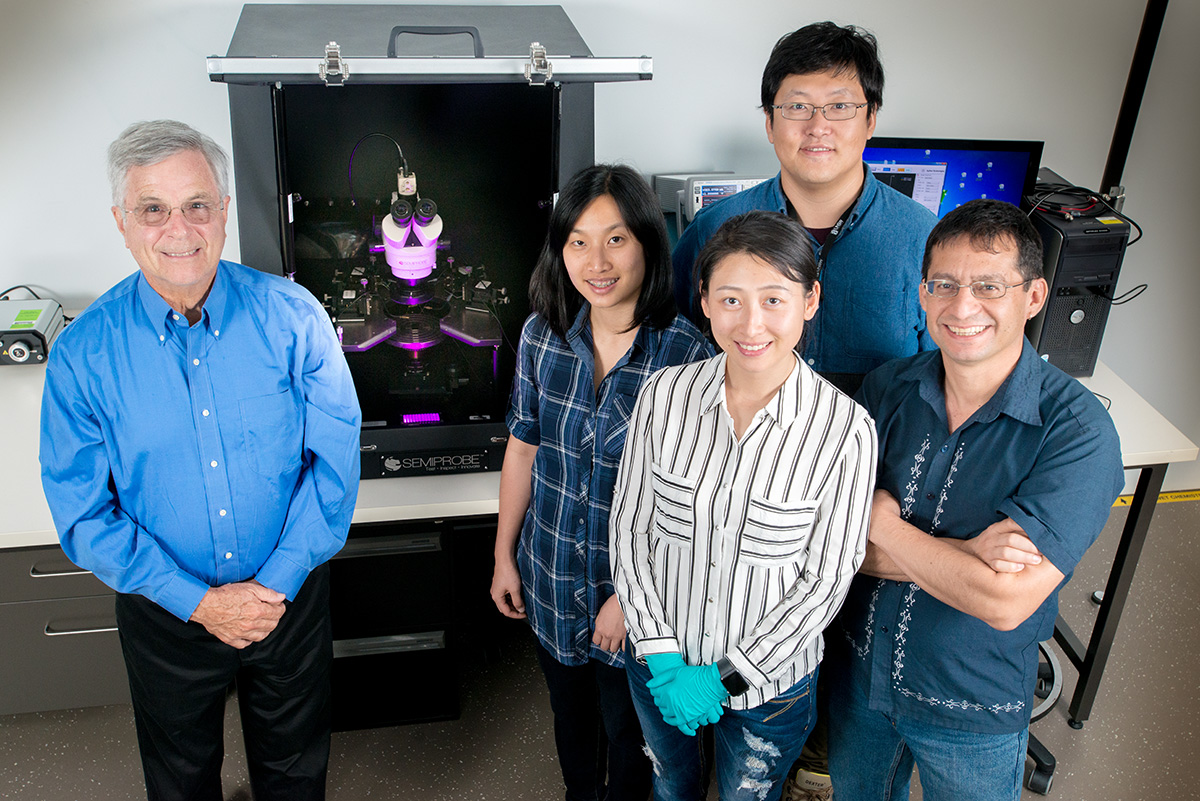

Supported by ARENA and led by world-renowned photovoltaics researcher Professor Allen Barnett, the team has created a lightweight, flexible and incredibly efficient solar cell that is perfect for high-altitude applications.

The limitations of silicon

Most solar cells are made of silicon, which has become cheap and readily available. But it has some limits when it comes to efficiency.

Sunlight is made up of light particles (photons) with a wide range of wavelengths. The shorter a photon’s wavelength, the more energy it contains, and the higher a voltage it can produce when converted into electricity.

However, silicon cells convert all photons to electricity at the same voltage. They can’t harness the energy contained in the low-wavelength, high-energy photons, which is one of the reasons why even the best silicon solar cells have been stuck at around 25 per cent efficiency for the past 20 years.

LIKE THIS STORY? SIGN UP TO OUR NEWSLETTER

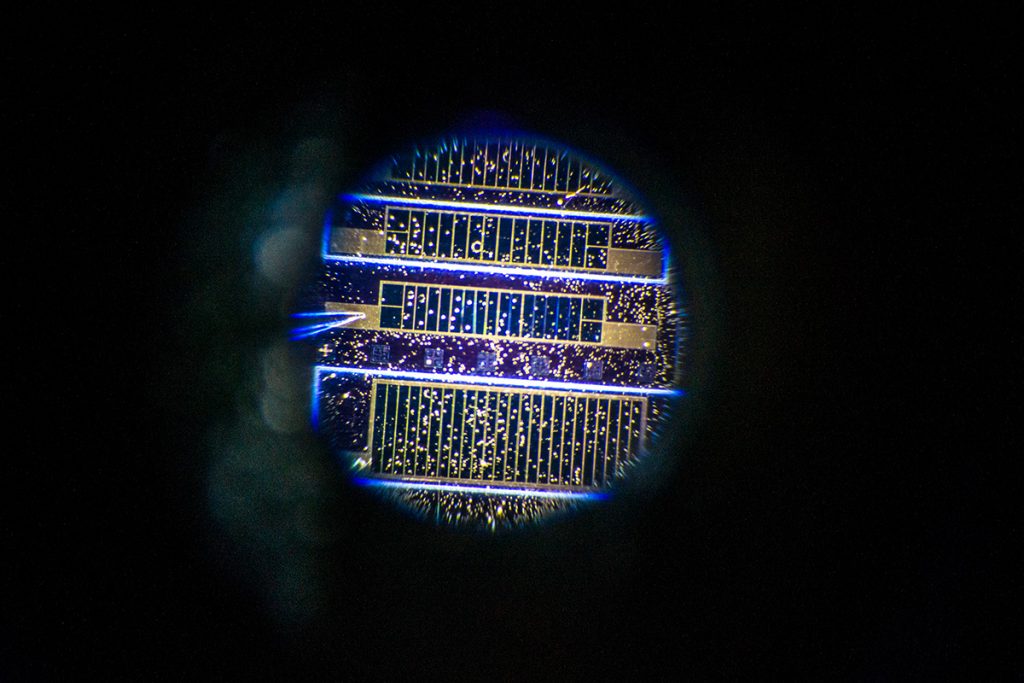

UNSW overcame this limitation by layering two extremely thin solar cells on top of each other. The bottom cell is a silicon alloy, while the top cell is made from Gallium-Arsenide-Phosphide (GaAsP).

The chemical properties of GaAsP let it capture the high-energy photons while letting the low-energy ones pass through to the silicon alloy layer. This dual-layer approach means that GaAsP solar cells could be up to 40 per cent more efficient than the best silicon cells in use today.

Spacing out

The downside of GaAsP cells? They’re still not as cheap as the silicon ones. And there isn’t much incentive for the makers of rooftop systems and solar farms to fork out for ultra-efficient cells when they could just add more panels. (However, Professor Barnett has calculated that GaAsP may be cost-effective for solar plants with sun-tracking technology, like the Moree Solar Farm.)

Of course there are some places where low weight, high efficiency solar panels are worth paying a premium for.

Like space.

“Most satellites today are owned by telecommunications or the military, who don’t care about the cost of solar cells.” Professor Barnett says. “But the new applications that are coming are commercial.”

Virgin, Airbus and SpaceX are just some of the companies looking at using swarms of low-orbit satellites for high-speed communications. Other tech firms – including Facebook and Google – want high-altitude, long-endurance unmanned aerial vehicles (drones) to deliver wireless internet to virtually any point on Earth.

All of these projects need solar cells that are extremely efficient, ultra-light and resistant to radiation from outer space.

“We can do a fifth of the cost and a fifth of the weight of the military stuff.” Professor Barnett says. “Our designs are also radiation-hard and flexible enough to be built into a curved airframe.”

How to grow a solar cell

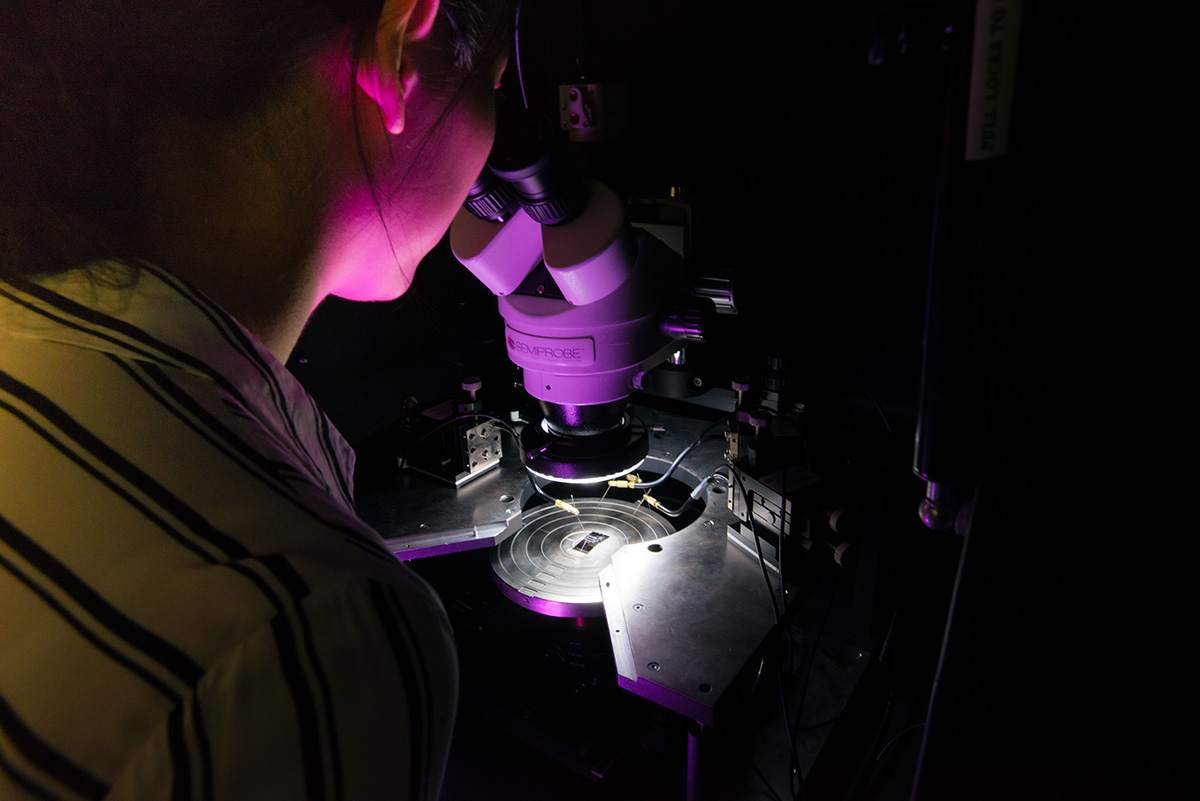

There are a couple of ways to make a multi-layer solar cell. “One is to just take two solar cells and glue them together, but that costs too much,” says Professor Barnett. “The other way is to grow them.”

That might conjure up images of farmers carefully nurturing fields of photovoltaic cells from seed, but growing a GaAsP cell is actually closer to baking than gardening.

A base layer of silicon is placed inside a vacuum-sealed reactor, which is heated up to 900ºC and filled with a vapour. This causes a chemical reaction that ‘grows’ incredibly thin layers of crystalline silicon alloy on the base. Layers of GaAsP are grown on top of the alloy using a different vapour before the pure silicon base layer is chemically removed.

The process takes less than five minutes and creates layers about 1/50 the width of a human hair, making GaAsP cells significantly thinner and lighter than a comparable silicon cell.

It’s also the same process used to make LEDs, meaning that manufacturing costs could be kept down by using existing tools and production lines.

Countdown to liftoff

The team has a few more steps to complete before GaAsP cells will be powering Facebook-branded drones or satellites.

“We have to get third-party validation of the efficiency and then we have to use these LED tools to get the cost of growing them down.” Professor Barnett says. “We’re still three to five years away.”

But the potential is definitely there: the UNSW team has already had private talks with a number of companies and estimates that the market for satellite and plane-based solar cells will be worth $700 million a year by 2025.

“In that range of efficiency, we are by far the lowest cost and the lowest weight.” says Professor Barnett. “We are the absolute leaders in this space today.”

Read the full knowledge sharing report from this completed ARENA project here.

This article was originally written by Simon Mitchell, Writer.

ARENA