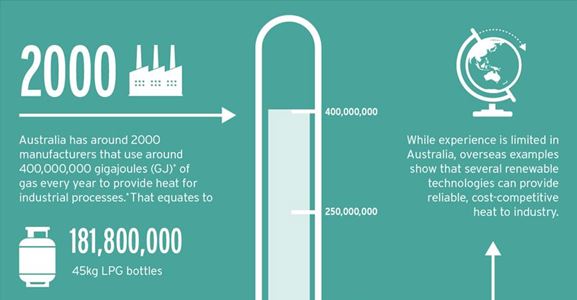

Did you know Australian manufacturers use 400,000,000 gigajoules (GJ) of gas every year to heat water, provide heat to produce steam, for drying, in ovens or as a chemical feedstock?

This gas is used in the processes to make pulp, paper, dairy, food and beverages, process meat, fabric, textiles or alumina.

Our latest infographic explains the reasons for growing interest in renewables for industrial processes and why it’s an ARENA investment priority.

Necessity drives innovation

The global demand for gas in recent years has put upward pressure on domestic gas prices rising and made it harder for industrial gas users to obtain long-term fuel supply contracts. Over the same period, renewable energy costs have decreased markedly.

With additional cost-reductions, and growing confidence that renewable technologies can be ‘fit-for-industry-purpose’, we commissioned a report on locally available renewable energy options for industrial production/manufacturing to replace or offset gas or other fossil fuels.

Could your industrial process use renewable energy?

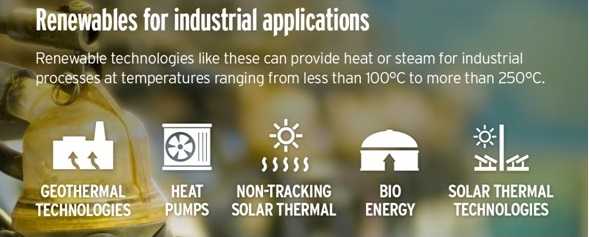

Depending on your circumstances, locality and renewable energy resource availability, renewable energy may be viable. Where biomass, waste, sunshine or geothermal resources are available, renewable energy technologies could match your industrial process heat need.

We’re looking for new projects

ARENA is looking for new projects that use renewable technologies for industrial processes. With an emphasis on driving down costs, we see opportunities to demonstrate the use of low or no-cost biomass or waste-streams or solar thermal in particular.

ARENA’s investment priorities aim for the best & biggest impacts

Areas where we can currently make the most impact are large-scale solar PV, integrating renewables and grids, renewables for industrial processes, fringe of grid and network constrained areas and off-grid areas.

Tomorrow’s Energy: accelerating innovation to make the transition to renewable energy faster, cheaper and easier.