Summary

The Alcoa Mechanical Vapour Recompression (MVR) for Low Carbon Alumina Refining project will seek to demonstrate the feasibility of integrating MVR, powered by renewable energy, to electrify steam production in the alumina refining process thus displacing fossil fuelled boiler steam. Alumina is the feedstock for aluminium production.

Need

The alumina refining sector is a valuable contributor to Australia’s economy. It is currently a significant fossil fuel energy user and therefore greenhouse gas (GHG) emitter and is categorised as ‘difficult to abate’ along with many other heavy industries. This project plots a pathway to enable alumina refining to substantially reduce emissions by using renewable power to drive mechanical vapour recompressors to displace fossil fuel derived thermal energy. It aims to provide confidence in MVR technology to enable further development and deployment necessary to decarbonise the refining process.

Learn more

Action

The project is a first-of-a-kind deployment of MVR in the alumina refining process in Australia. It will be delivered in two stages.

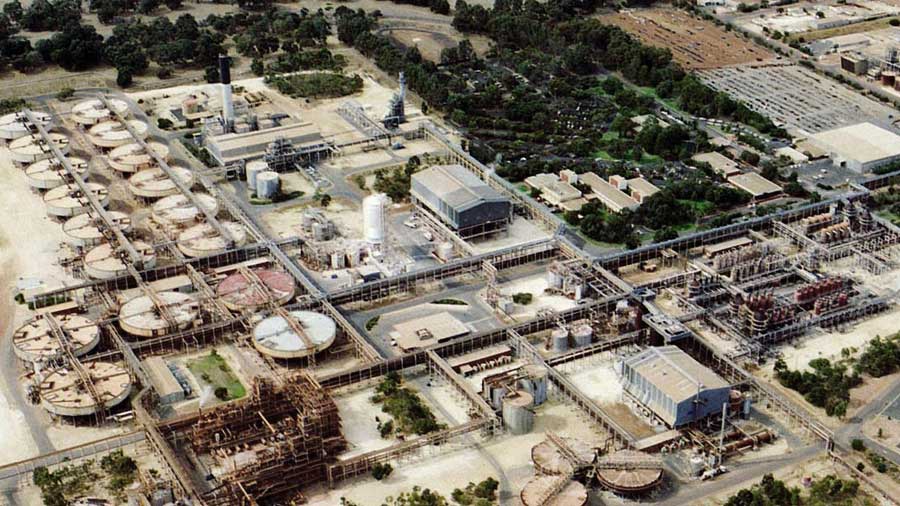

Stage 1 has two engineering study streams. One stream will investigate the technical feasibility and commercial viability of integrating MVR powered by renewable energy in Australian alumina refining processes and consider the commercialisation pathway to retrofit the technology at existing alumina refineries. The other is to complete a detailed feasibility study for implementation of a full scale 3 megawatt (MW) MVR module at Alcoa’s Wagerup Alumina Refinery in Western Australia.

If the feasibility study indicates the installation will be technically and commercially viable, the project will proceed to Stage 2. This involves detailed design, procurement, execution, deployment, integration, commissioning and operation of the full-scale 3MW MVR module. The MVR module will be integrated with the refinery’s evaporation step of the alumina refining process and will be powered by renewable energy.

Outcome

Electrifying steam production in the evaporation aspects of the alumina refining process could displace fossil fuel boiler steam production in the process. Demonstrating successful operation of the technology for evaporation could enable its use to be extended to other process duties, further displacing fossil fuels. Using renewable energy as opposed to fossil fuels based energy would reduce GHG emissions from the refining process Demonstrating the commercial viability of this project would show renewable energy can be cost-competitive or cost-beneficial relative to fossil fuel use. This would provide an incentive for the industry to evaluate and potentially adopt the technology.

Additional impact

This project will improve the alumina industry’s understanding of how to retrofit existing and build new low carbon footprint alumina refineries thereby supporting its future viability and competitiveness.