Summary

Australia’s sugar industry is worth more than $2 billion per year and is the third largest exporter of raw sugar globally. While the industry produces considerable renewable energy (electricity and steam) from bagasse, this Utilising Biogas in Sugarcane Transport and Milling project will explore opportunities exist to utilise sugarcane trash, or field residues remaining after harvesting. This is currently considered to be an uneconomic way of generating energy.

Key results

The Biogas from Sugarcane project identified opportunities to reduce fossil fuel use across the sugar industry. Activities undertaken within the project have advanced the project concept based on the use of sugarcane trash and/or bagasse as a bioenergy feedstock, with the potential to be converted into fuels, to replace diesel initially in sugarcane transport and in the future in sugarcane production. Analysis has identified that the digestion and upgrading of as little as 10% of the available trash from sugarcane regions would completely satisfy the requirements for diesel use on a farm and in sugarcane and sugar products transport.

Supply chain modelling work undertaken in the project assessed the relative supply chain costs of various sugarcane trash collection strategies. It was identified that, while there are regionally specific issues associated both with the availability of sugarcane trash and with the optimal solutions, in general the lowest cost trash collection strategy is to collect trash during harvesting and transport to the factory, for separation from the cane, prior to milling. The novel trash separation and recovery technology has demonstrated fit for purpose use, but requires further scale-up towards full commercial size for full validation.

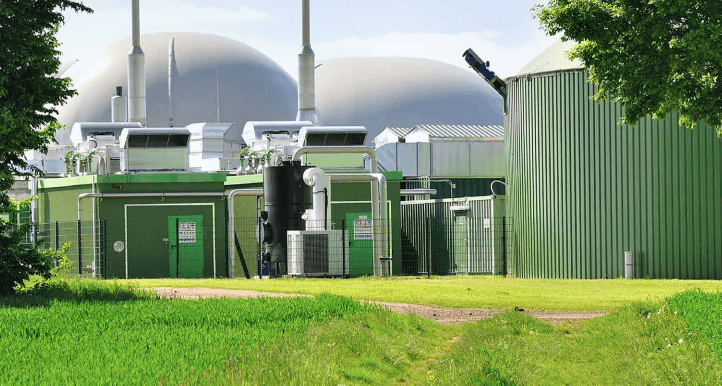

This project has developed new capacity and capability for bioenergy and biogas related research in Australia. In particular, the development of the integrated biogas reactor, compression and upgrading system will be of significant value to the Australian research and bioenergy communities.

Learn more

Project innovation

The Utilising Biogas in Sugarcane Transport and Milling project involves the unique utilisation of two biomass conversion technologies to significantly improve the efficiency and economics of biomass conversion for the production of biogas and liquid transport fuels.

Sugarcane trash and bagasse will be converted to biogas and upgraded to biomethane for use in sugarcane farming and transportation. Solids from biogas production will be converted via hydrothermal liquefaction to biofuels and chemicals.

The integrated project plan includes the development of biomass separation and pretreatment technology through to the production of usable energy products.

Benefit

The Utilising Biogas in Sugarcane Transport and Milling project will deliver an assessment of the feasibly of integrating bioenergy technologies within the sugarcane production and milling process.

Biogas and transport fuels produced using sugar cane trash and surplus bagass could significantly reduce the need for conventional fossil fuels used in farm machinery, sugarcane and sugar products transport, and supplement fuel for cogeneration during the non-crushing season.

Read more about bioenergy and energy from waste.