Summary

The SunDrive Copper Metallisation Demonstration project aims to progress SunDrive’s copper electrochemical solar cell technology to the next stage of commercialisation.

Key results

The primary purpose of this project was to demonstrate the manufacturability of SunDrive’s copper electroplating technology. As passivated emitter and rear cell (PERC) solar cells reach their theoretical efficiency maximums, the industry is looking to new technologies such as heterojunction (HJT) to further increase efficiencies, though this comes at significantly higher financial and environmental cost.

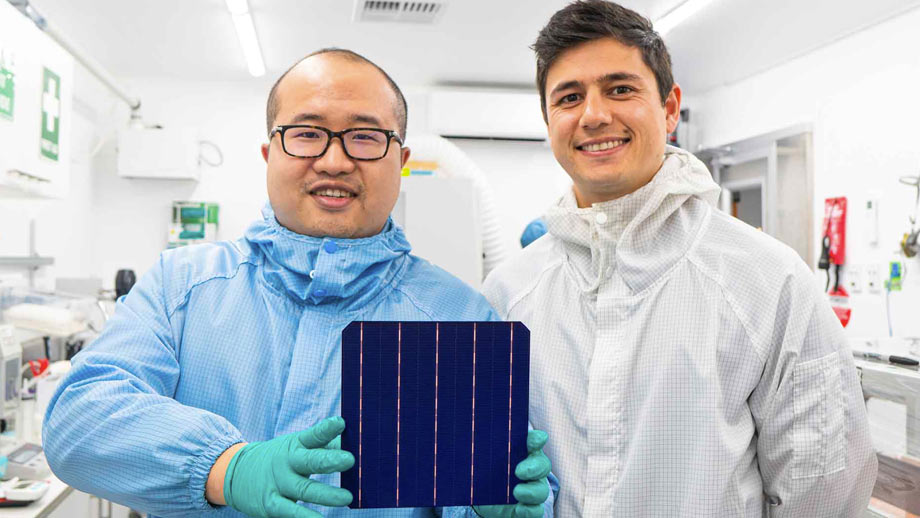

SunDrive has addressed these costs by replacing silver with copper on a semi-automated prototype production line that improves the cost and efficiency of silicon (Si) HJT cell production.

The project improved cell design knowledge and understanding of cell characterisation and processing requirements leading to the achievement of a world record efficiency in 2021.

Learn more

Need

The SunDrive Copper Metallisation Demonstration project acknowledges that approximately three percent of the world’s electricity is generated from solar photovoltaic (PV) technology. If solar PV is to become the dominant global energy source in the coming decades, then more advanced solar cells will be required.

A key barrier to the broader adoption of next generation solar cell technologies is the use of silver. Solar manufacturing represents an estimated 20% of annual global industrial silver consumption. This will be exacerbated as the industry attempts to move to higher efficiency cell structures which require two to three times more silver per cell, presenting an ongoing supply risk if solar demand is to grow five-fold as predicted within the next decade.

Action

SunDrive is attempting to solve this issue through developing its copper electrochemical process which replaces silver with copper. The project will help to commercialise SunDrive’s technology through achievement of the following objectives:

- iterate the cell design and processing requirements to improve cell efficiency

- scale the technology from individual industrial-size cells to a commercial-size module

- develop and demonstrate a small-scale prototype automated production line.

Outcome

The project aims to progress SunDrive’s technology to the next stage of commercialisation, where further funding can be raised to deploy a large-scale pilot production line to fabricate SunDrive’s proprietary copper-based solar cells. These cells are expected to be higher in efficiency and lower in cost compared to currently-best-available silver and other competing copper methods.

SunDrive will initially focus its technology on the distributed and rooftop solar sector, where space is at a premium and where higher efficiency cells can produce greater amounts of energy.