Summary

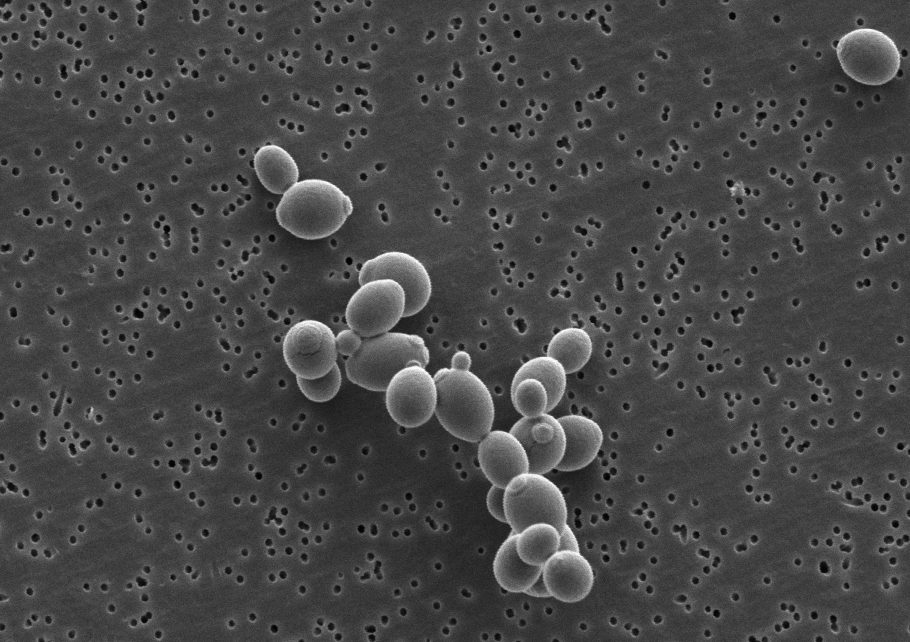

The small Australian biotechnology company Microbiogen is aiming to breed a strain of yeast that will produce a more efficient and economical form of bio-fuel from non-food sources and aim to transform the global ethanol industry.

Key results

Microibiogen successfully manufactured an efficient and high yielding organism for the production of biofuels from non‐food sources. The implications of the successful program are significant:

- An estimated 25% effective reduction in operating costs of producing renewable lignocellulosic ethanol

- High value single cell protein as a by-product from non-food biomass

- The more biofuels manufactured, the more high-value protein produced

- If Australia converted just its sugar cane bagasse using the Microbiogen optimised organism and process, then enough ethanol would be produced to replace nearly 10% of petrol and replace nearly 140,000 tonnes of currently imported protein feed

- Peer reviewed Life Cycle Analysis (LCA) shows a 29% reduction in CO2, 11% decline in fossil energy use and a massive 240% decline in land use – compared to the commercial yeast biocatalyst.

In an environment where many believe that the future is all electric, the results achieved by Microbiogen show that an ‘all of the above’ approach makes more sense. The ability to lower CO2 emissions faster, diversify risk away from a single technology approach, adding to the food supply and holding out the potential to have biofuel production extract CO2 from the atmosphere, are important issues to consider outside of just trying to reduce emissions.

The results from this project present Australia with the potential to reduce expensive protein imports, develop new export markets and develop an alternative supply to industries, such as the military, heavy marine transport, heavy road transport and more.

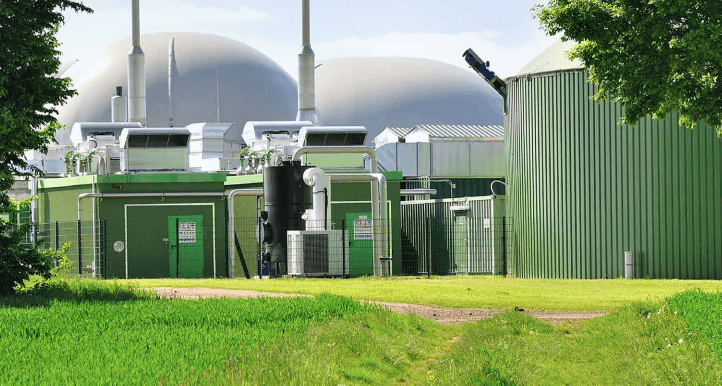

Microbiogen has partnered with one of the world’s largest industrial biotechnology organisations to apply its unique breeding processes and traits on genetically modified yeast. This Biocatalyst Optimisation & Deployment project will in turn cause the production of bioethanol from plant waste cheaper and more efficient by speeding up the process of fermentation.

Learn more

Project innovation

This Biocatalyst Optimisation & Deployment project successfully optimises and deploys the world’s most efficient and high yielding organism for the production of biofuels from non‐food sources.

Benefit

This Biocatalyst Optimisation & Deployment project will reduce the cost of producing biofuels from non-food sources through the optimisation of yeast strains that can more efficiently convert sugars to bioethanol. In this way, MBG will advance the commercial development of renewable energy and enabling technologies (e.g., Biofuels). By extension, more biofuel availability means renewables at a lower cost.

One of the key issues for the deployment of plant based biofuels globally and in Australia is the relatively inefficient biocatalysts available to produce biofuels. The MBG project will help drive forward the technology innovation chain with respect to biofuels from biomass.

Read more about bioenergy and energy from waste.