More than 3 million Australian households now have rooftop solar installed. That’s more per capita than any other nation.

All that solar energy is helping us to switch our electricity system to clean energy. But it also causes its own headaches, particularly in the critical area of grid stability.

In March, the CSIRO released the Renewable Energy Storage Roadmap report. It predicts Australia will need a massive increase in energy storage to support the renewable energy transition. By 2030, the roadmap predicts the National Energy Market will need six times more than is available today.

Even once pumped hydro storage projects like Snowy 2.0 are up and running, there is still expected to be a shortfall of 11 GW of storage capacity needed to firm up the variable renewables in our electricity system.

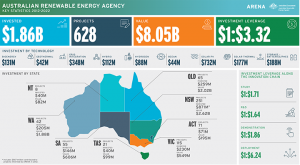

Large scale batteries, like the eight grid-forming projects supported by ARENA’s recent $176 million funding round, are already making a major contribution.

But what about energy storage at a more local, community level?

Individual solar-owning households appear reluctant to install home batteries. Roughly, only 180,000 have done so, although that figure is growing.

Community batteries might be the missing link in our energy storage needs. They could provide energy storage both for the distribution network and for local needs.

Lower bills and emissions, greater grid stability

At times of plentiful solar generation, such as the middle of the day, the battery can be charged. At times of local peak demand or at night, stored energy can provide power back to the community and ease grid constraints.

But community batteries are a relatively new and untried technology. They are still rare in Australia and globally.

The problem is in the detailed understanding of how they might operate in the real world.

That’s why ARENA is rolling out a funding program to fix that knowledge gap and understand how to scale-up their use.

ARENA CEO Darren Miller said community batteries represent the next step in optimising distributed energy resources in the electricity grid.

“Not everyone is able to install rooftop solar, but by storing electricity close to the point of consumer demand, we can reduce network costs and alleviate constraints in areas with high solar penetration. This will ultimately reduce electricity costs for all consumers,” he said.

The $171 million program administered by ARENA will support 342 community batteries to be built across Australia.

As part of the Federal Budget 2022/23, the Albanese Government committed to build 400 community batteries across Australia. A further 58 batteries are to be funded under a separate program which recently closed.

Overall, the program is intended to lower energy bills, cut emissions, reduce pressure on the grid and support more rooftop solar being installed.

More detailed questions to be addressed include around the economics of community batteries, battery size and configuration, business models, and the pros and cons of both front-of meter and behind-the meter setups.

ARENA expects the initial $120 million round will provide valuable lessons to inform industry and future applicants for a second round.

What are community batteries?

Community batteries fit into the renewable energy storage gap between small, household batteries and big, utility scale batteries.

Household batteries are typically in the 5 kWh to 15 kWh range, whereas the most recent grid-scale battery projects to receive ARENA funding are up to 20,000 times larger.

Community battery projects are expected to occupy the middle ground with between 50 kW and several megawatts nameplate capacity.

In terms of size and appearance, community batteries can range from a fridge to a small shed, or as big as a shipping container.

An ARENA supported trial in Alkimos Beach, Western Australian connected 100 households to a 1.1 MW community battery.

Participating households shared in $81,376 of power bill savings over the five-year trial.

Benefits for network operators and retailers included reduced electricity consumption during periods of high demand for grid power.

At the other end of the scale, United Energy is installing community batteries the size of fridges mounted to power poles in south eastern Melbourne under an ARENA-funded trial.

What is Round 1 funding?

Round 1 of ARENA funding is split between two streams:

- Stream A: Distributed Network Service Providers (DNSPs)

- Stream B: Applicants that are not DNSPs

Under this round, each applicant must plan to connect a minimum of five batteries to the electricity distribution network.

Each battery must be within the range of 50 kW to 5 MW in size.

Batteries that are co-located or share a connection point will be considered a single community battery.

Expressions of Interest opened in early April for between $3 million to $20 million in funding.

However, projects should be completed within 24 months of execution of an agreement.

Projects that require more planning and development should keep an eye out for details of Round 2 funding. More details for Round 2 are expected to be announced in late 2023.

ARENA will be hosting two information sessions on the Community Batteries Funding Program in April.

Further information on how to apply can be found at ARENA’s funding page.

LIKE THIS STORY? SIGN UP TO OUR NEWSLETTER